Batch record management

/Equipment Integration

Equipment Integration

ProFlow Batch Management is designed to seamlessly integrate with manufacturing equipment, enabling automated batch record generation while maintaining compliance with GMP and regulatory requirements. The integration ensures complete traceability and eliminates manual effort during data capture and processing.

How It Works

The system communicates directly with production equipment using predefined configurations to capture essential batch data. The workflow includes:

- Data Capture: Manufacturing equipment is configured to send batch data automatically upon process completion.

- Batch Documentation: The system retrieves key information, including equipment type, document type, batch number, and timestamps.

- Seamless Integration: ProFlow ensures real-time synchronization between equipment outputs and the batch management system, ensuring no data is missed.

Alternative Integration via File Server

In many organizations, production equipment is automatically connected to a central file server. Instead of directly integrating with individual machines, ProFlow can interact with the file server to retrieve batch-related data. The process involves:

- File Server Monitoring: Equipment-generated batch records are automatically stored on a designated server folder.

- Scheduled Retrieval: OBS periodically checks the server directories—typically every hour—for new files.

- Automated Processing: Once new files are detected, they are imported into OBS, triggering batch processing and documentation workflows.

This approach simplifies integration, reduces the number of direct connections to equipment, and ensures a standardized method for retrieving production data.

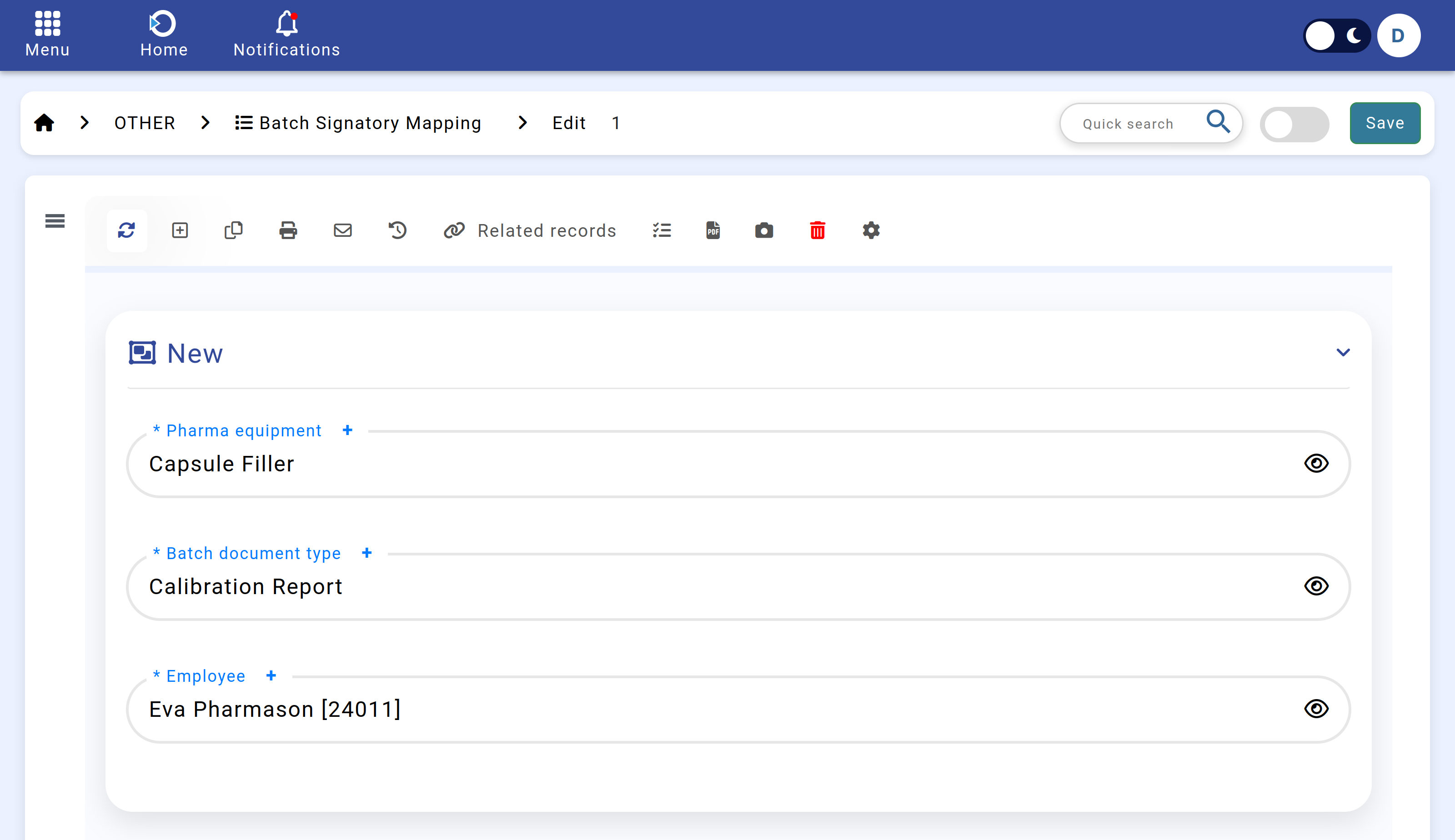

Automated Approval Assignment

ProFlow streamlines the approval process by dynamically assigning approvers for each batch record. This automation eliminates the need for manual intervention and ensures compliance with regulatory standards. Key factors influencing the assignment include:

- Equipment Type: Ensures that only qualified personnel review equipment-specific records.

- Batch Document Type: Approvers are assigned based on the document’s nature, such as Calibration Reports or Cleaning Records.

The automated approval assignment reduces the risk of errors, increases efficiency, and ensures that the process adheres to predefined workflows and compliance requirements.

Navigation: Home screen > Batch Record Management > Batch Signatory Mapping.